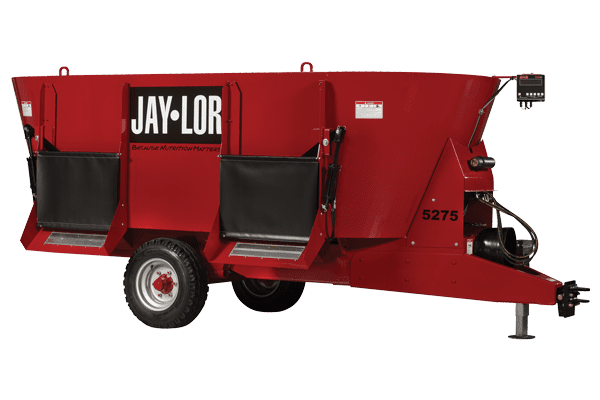

The New 5275 Mini-Mixer has been specifically designed to process bales up to 4’x5’ into a uniform TMR that resists sorting. Even the smallest skid steers won’t have any trouble loading this 300 cubic foot (8.5m³) model and just 45 Horsepower will run it. On smaller operations, or when feeding specialty groups, such as weaned calves or dry cows, the Mini Mixer Series fits perfectly.

The New 5275 Mini-Mixer has been specifically designed to process bales up to 4’x5’ into a uniform TMR that resists sorting. Even the smallest skid steers won’t have any trouble loading this 300 cubic foot (8.5m³) model and just 45 Horsepower will run it. On smaller operations, or when feeding specialty groups, such as weaned calves or dry cows, the Mini Mixer Series fits perfectly.

“We’ve used our decades of experience building larger TMR mixers to engineer the same capabilities and durability into this model.” Craig Darroch, Lead Engineer on the project, says. “Since the release of our Mini Mixer Series in 2010 with the 50 cubic foot (1.4m3) model we’ve had requests to fill the gap. The first step was a 100 cubic foot model released in 2011 and now with a 275 cubic foot model we truly have a mixer for every size of farm.” Jaylor manufactures 15 models from 50 cubic feet (1.4m3) to 1295 cubic feet (36.7m3) and everything in-between.

ULTRA-LOW LOADING

The Ultra-low loading height makes this possibly the lowest TMR mixer available that can process a 4’x5’ round bale. Even the smallest skid steers will have no problem loading this model. Another advantage noted by early users of the 5275 model is that it’s possible to see over the top of the from the tractor seat making navigating through tight alleys a breeze even in reverse.

LOWEST HORSEPOWER

With a Horsepower requirement of only 45HP, the 5275 has the lowest horsepower requirement of any vertical TMR Mixer in its class. Jaylor attributes this low horsepower requirement to the unique design of the slide plate on their patented auger. The concept is simple; the feed is gently gathered into the auger for elevation in a way that decreases friction. Less friction results in reduced power consumption, which translates to low horsepower required and ultimately lower operating costs. Reduced friction also means less wear and tear and longevity of the machine.

FEATURES AND OPTIONS

Regular maintenance is simplified with the central greasing bank, which routes the grease ports conveniently to an area located near the hitch. An optional 6” plastic extension is available to increase the capacity to 375 cubic feet (10.6m3) A complete weighing system comes standard on the 5275 model TMR Mixer with a DG500 indicator. This system is compatible with the full range of scale options and upgrades Jaylor offers including remote indicators, zero resets, wireless controls, and feed management software.

THE SQUARE-CUT AUGER

The 5275, along with every other Jaylor Model, comes standard with Jaylor’s patented Square-Cut Auger which produces a quality mix faster and cleaner. A fundamental feature of the Jaylor auger is the ‘Square Cut’ edges that contribute to its industry-leading ability to process baled forage and other roughage, and mix it into a uniform TMR that resists sorting. The improved cutting action means less pressure on the mix and improved feed ration for your animals. The patented sloped top prevents bridging of round bales, allowing them to be rapidly cut apart while increasing the mixing action. The unique slide plate gently and efficiently gathers the feed into the auger for elevation in a way that decreases friction on the feed, reducing horsepower requirements by 20%. Less friction results in reduced power consumption, which translates to lower operating costs for you. Jaylor uses specially designed and oriented knives for maximum cutting efficiency when processing long forage. They are self-sharpening, selected and tested for durability and long life.

Jaylor has innovated in many areas but the auger is where the magic happens. “It’s a square cut which allows feed more quickly reach the bottom so you have a quicker mix and more efficient processing.” says Jake Tamminga, President of Jaylor. “The knives are located on the corners of the auger which give it a more efficient cut by using a slicing motion instead of forcing them into the feed. That’s why our mixers take less horsepower; when you take excess horsepower that energy is wasted in the destruction of fiber.” Tamminga adds.

Jaylor has innovated in many areas but the auger is where the magic happens. “It’s a square cut which allows feed more quickly reach the bottom so you have a quicker mix and more efficient processing.” says Jake Tamminga, President of Jaylor. “The knives are located on the corners of the auger which give it a more efficient cut by using a slicing motion instead of forcing them into the feed. That’s why our mixers take less horsepower; when you take excess horsepower that energy is wasted in the destruction of fiber.” Tamminga adds.

With traditional round augers bales tend to stay at the top of the mixer for a long time, especially on smaller units. The open sections of the Jaylor Square-Cut Auger allow the bale to quickly drop where the lower knives can break it apart and process it faster. The patented sloped-top prevents the bale from ‘sitting’ on top of the auger and ensures the auger can break it apart. The Tungsten Carbide coating on the knives creates a harder surface on the top, allowing the bottom to wear faster which keeps the knives sharp.

BECAUSE NUTRITION MATTERS

Center to the philosophy at Jaylor is nutrition. This is why a Shaker box is made available, allowing producers to monitor and evaluate their ration on a daily basis. Mix uniformity and resistance to sorting define the optimum TMR mix. A TMR mix is the result of an interaction between mixer design and performance, ingredient characteristics, and operating procedures. The Shaker Box provides a simple way to test the uniformity of particle size and ingredient distribution within a batch, as well as between loads. This also enables fine tuning of mixing procedures to create the optimum mix, as well as to monitor mixer performance. “You may already have a nutritionist, and that’s perfect.” says Dr. Alan Vaage, Ruminant Nutritionist for Jaylor “At Jaylor we want you to think of us as your ‘feed mixer’ nutrition specialists. When you purchase a Jaylor mixer, we are at your service, so please feel free to email us, anytime, at nutrition@jaylor.com. We’ll answer all your nutrition questions. That’s what goes with being a Jaylor customer!”

WARRANTY

Jaylor stands behind their products and offers the most comprehensive warranty in the industry. A 5 Year Frame Warranty comes standard guaranteeing against faulty workmanship and materials. All you have to do is register, and if ever there is a problem within those five years, they’ll take care of it. The DG weighing system comes with a 4 Year Warranty and Jaylor also offers a 1 Year warranty on all other components of the entire mixer.

Jaylor Fabricating Inc., is located in Dufferin County, Ontario and Manufacturers TMR mixers for the beef and dairy industry. With 25 patents currently on the mixer and an additional 7 pending, the Jaylor Mixer has earned a reputation as a leader in the business, Jaylor was built upon word of mouth and success on farms. Its reputation for high quality spread rapidly, ensuring Jaylor mixers were soon distributed throughout North American and over 50 countries world-wide. Today Jaylor is a successful international corporation, but has never forgotten where it started and still maintains its roots firmly planted on the farm, with its production facilities located in rural Ontario.