Jaylor is an industry leader in its class at quickly processing baled forage into uniform rations, eliminating cattle’s sorting behaviour while eating.

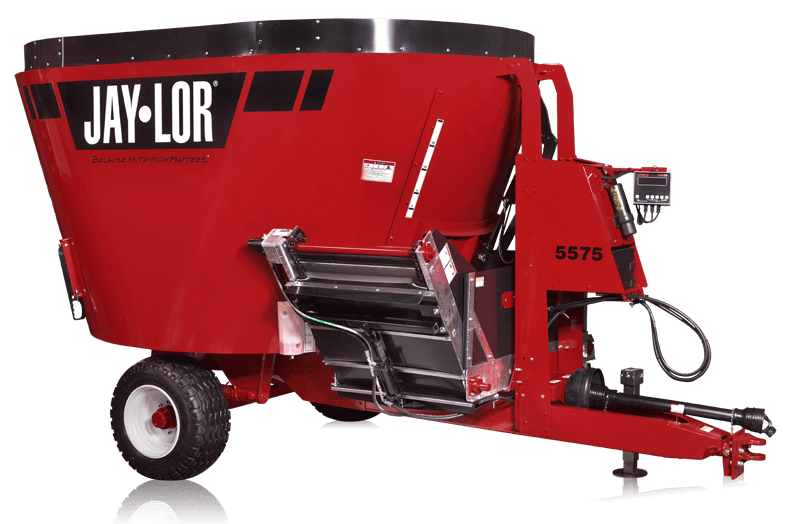

Our Single Auger Mixers are ideal for feeding small to mid-sized dairy and cow-calf operations. Medium-sized beef backgrounding and grower operations, as well as large sheep and goat facilities, will especially benefit from the patented features of our single auger feed mixers.

The 5400 is a “low-profile” machine and ideal for use with smaller skid-steer loaders, or wherever height is limited. All Jaylor mixers come standard with the patented Jaylor augers and the full range of innovations, warranties, and with a full range of options to create your tailored feeding solution. Our Single Auger Mixers is a key part of our Vertical TMR Mixers lineup. Explore our other products to find the perfect fit for your needs!

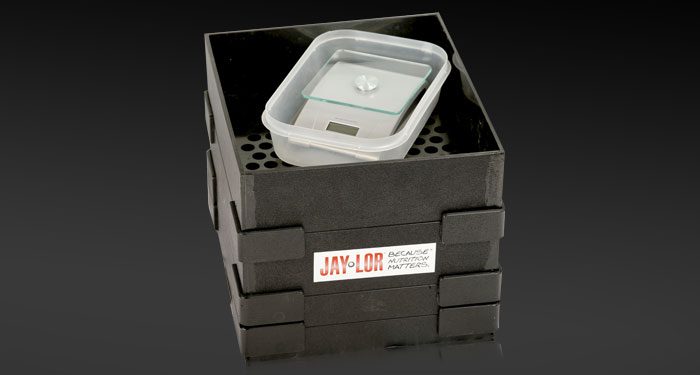

- Three-Point Weigh System

- Rapid Discharge Door

- Galvanized Discharge Conveyor

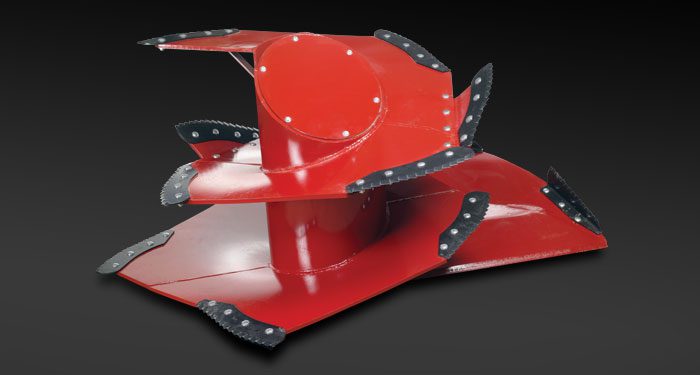

- Sloped Top Square Cut Auger

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Shear Bolt Protection

- Mixer Level Indicator

- Heavy Duty Single Straight Axle & Hubs

- Mix Viewing Window

- Restrictor Blades (2)

- Adjustable Cast Hitch

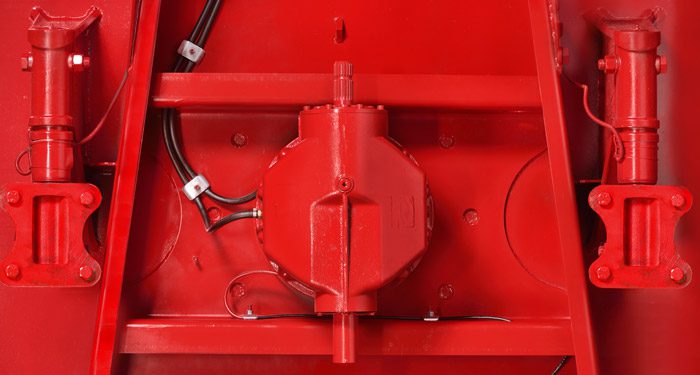

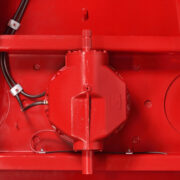

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir

- Shaker Bo

Our farm uses the Jaylor 4425 TMR Mixer, and it easily shaves off 30 minutes of our workday. No more hay flying out of the mixer. It’s the Cadillac of all mixers. – Moyerdale Farms Ltd.

We noticed an instant change in butterfat production, dry matter intakes and more after buying a Jaylor 4425 TMR Mixer. We will never go anywhere else. – Ridgeview Dairy

We background around 1500 head of beef cattle and use the Jaylor 5575. We’ve had three machines, and they always get the job done right. – Seven Springs Farms

We’re delighted with our Jaylor mixer. The freedom it gives us to put whatever we want into the ration is excellent. The mix is consistent is finished within minutes. The machine is well built, performs fantastic and is exactly what we needed. – Vanden Elzen Farms

Single Auger TMR Mixers FAQs

Jaylor’s Single Auger TMR Mixers offer several advantages:

- Patented Square-Cut Augers for efficient mixing and reduced power requirements

- Rapid processing of baled forage into uniform rations

- Prevention of cattle sorting behavior while eating

- Versatility for various operation sizes, from small dairy farms to large sheep facilities

- Durable construction with features like tungsten carbide-coated knives and welded mixing chambers

Jaylor Single Auger Mixers are industry leaders in quickly processing baled forage into uniform rations. They can achieve a uniform mix in as little as 3 to 5 minutes, which is more efficient than many conventional mixers. This rapid processing helps prevent cattle from sorting their feed and ensures a balanced diet

Jaylor offers four models of Single Auger TMR Mixers:

- 5350: 350 ft³ (9.9 m³) with extensions available to increase capacity up to 425 ft³ (12.0 m³).

- 5400: 375 ft³ (10.6 m³) with extensions available to increase capacity up to 465 ft³ (13.2 m³).

- 5425: 450 ft³ (12.7 m³) with extensions available to increase capacity up to 540 ft³ (15.3 m³).

- 5575: 475 ft³ (13.5 m³) with extensions available to increase capacity up to 575 ft³ (16.3 m³).

Key features include:

- Patented Sloped Top Square-Cut Augers

- Three-Point Weigh System with DG500 Indicator

- Rapid Discharge Door

- Galvanized Discharge Conveyor

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Mixer Level Indicator

- Heavy Duty Single Straight Axle & Hubs

- Mix Viewing Window

- Adjustable Cast Hitch

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir.

The minimum horsepower requirements for Jaylor Single Auger TMR Mixers vary by model:

- Jaylor vertical TMR mixers require less horsepower to operate as compared to conventional round auger mixers.

- 5350 Single Auger: 60 HP

- 5400 Single Auger: 70 HP

- 5425 Single Auger: 70 HP

- 5575 Single Auger: 80 HP

Jaylor Single Auger TMR Mixers are ideal for:

- Small to mid-sized dairy and cow-calf operations

- Medium-sized beef backgrounding and grower operations

- Large sheep and goat facilities

- Operations requiring efficient processing of baled forage

The patented Sloped Top Square-Cut Auger in Jaylor Single Auger Mixers offers several benefits:

- It creates a more uniform Total Mixed Ration (TMR)

- Reduces power requirements compared to conventional round auger mixers

- Enables efficient processing of baled forage

- Helps prevent cattle from sorting their feed, ensuring a balanced diet

The Three-Point Weigh System with DG500 Indicator serves multiple purposes:

- Provides accurate weight measurements of feed ingredients

- Allows for precise ration formulation

- Helps operators monitor feed consumption and adjust rations as needed

- Enhances overall feed management efficiency

The Rapid Discharge Door offers several advantages:

- Enables quick and efficient unloading of the mixed ration

- Helps maintain the consistency of the mix during discharge

- Reduces overall feeding time, improving operational efficiency

- Allows for more precise feed distribution

The Welded Mixing Chamber is an important feature because it:

- Enhances the overall durability of the mixer

- Provides a seamless interior surface for improved mixing efficiency

- Reduces the potential for feed buildup and contamination

- Contributes to the longevity of the equipment

The Mixer Level Indicator is a helpful tool for operators as it:

- Provides a visual reference for the amount of feed in the mixer

- Helps prevent overfilling, which could reduce mixing efficiency

- Assists in achieving consistent batch sizes

- Contributes to overall operational efficiency and feed management

Yes, Jaylor Single Auger TMR Mixers offer a variety of optional features to meet specific needs, including:

- Various door configurations (Rear Door, Corner Door, Center Side Door)

- Different conveyor options (Left or Right Discharge, Dual Discharge Flat Conveyor, Flip-Up Conveyor, etc.)

- HD Axle with Dual Tires

- Angling Blade Auger

- Additional Alexander and Vertical Knives

- Plastic Extension Upgrade for Increased Capacity

- 2 Speed Transmission