Twin Auger TMR Mixers

Built for larger loads and demanding operations, Jaylor’s Twin Auger TMR Mixers create a consistent mix—fast. The patented dual Square-Cut Augers handle round and square bales with ease, blending forage, silage, grain and more into a balanced ration that reduces sorting and feed loss.

Jaylor's Twin Auger Mixer Line-Up

5850 TMR Twin Auger

Capacity:

800ft³ | 22.7m³

up to

960ft³ | 27.2m³

*with extensions

4×5 Round Bales:

4 Bales

5×6 Round Bales:

2 Bales

3x4x8 Square Bales:

3.1 Bales

Height:

108in | 274cm

Length:

308in | 782cm

Drum Width:

97in | 246cm

Capacities noted above will vary with the density of the hay in the bales and other factors.

We’re here to discuss your needs and help you find the right mixer for your operation.

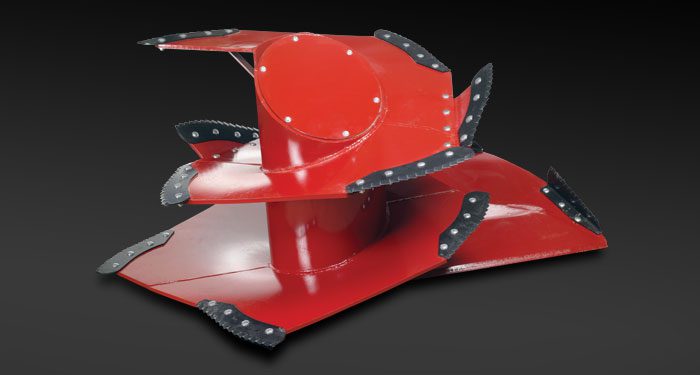

The Square-Cut Auger is what sets Jaylor apart. In our Twin Auger TMR Mixers, it processes tough forages and blends silage or grain into a uniform TMR in minutes—boosting feed efficiency and giving you full control over what your herd eats.

Save time while using 20% less horsepower.

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor TMR mixer reduces fuel consumption and ensures a longer operating life. It is conservatively estimated that Jaylor feed mixers can save $12,000 per year in operating costs compared to conventional mixers on a typical farm.

Tap on the Square-Cut Auger below to see what makes it such an innovation.

Have questions?

Unsure what machine is right for your operation?

Need to find a dealer or schedule a demo?

- 3 Point Weight System

- Rapid Discharge Door

- Galvanized Discharge Conveyor

- Sloped Top Square Cut Augers

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Shear Bolt Protection

- Mixer Viewing Window

- Restrictor Blades (2)

- Adjustable Cast Hitch

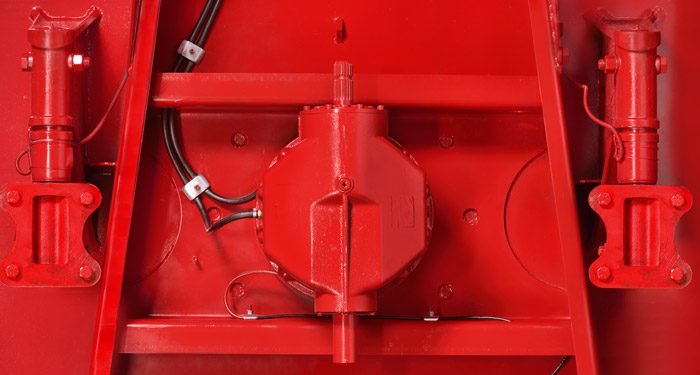

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir

- Central Greasing Bank

- Shaker Box

We have a Jaylor 5575, and it’s our second piece of Jaylor equipment. We’ve only had to do regular maintenance on the machine, which makes using the mixer simple and convenient. – Ash Grove, Missouri

What made me buy a Jaylor mixer was that it was reliable and built solid. I love the cut length of the mix, the consistency and the increase of our cattle’s dry matter consumption. They love the mix. – Ferme Champsélisé

I decided to go with a vertical mixer after I was tired with the mess of traditional mixers. We weighted the calves after the first year with the Jaylor 4650, and they came in about 6/10ths of a pound better than any other year. – Napoleon North Dakota

I see a well-blended mix with the Jaylor. It’s evenly distributed, cuts uniformed grass lengths, and has excellent maneuverability. Our Jaylor keeps up with the demand of farming wetland and puts up with the number of miles we put it through. – Triple Son Farms

We have a 2500 head dairy herd, milking about 2100 head, while running 7 Jaylor mixers on all of our TMR work, milk cows and heifers, replacements, and some steers. – Robey Farms

We used to have to bring in dry hay to feed our cattle, but our Jaylor 5850 allows us to mix our own bales without loss or mess. As a result, the production of butterfat increased from 33%-37% after our first year! – East Cardson Colony

Twin Auger TMR Mixers

More Capacity. More Control. The Jaylor Difference.

Jaylor Twin Auger TMR Mixers deliver powerful performance and precise feeding control across a wide range of herd sizes. With two of our patented Square-Cut Augers, these mixers process round or square bales into a uniform, high-quality ration that helps reduce sorting and improve intake.

Built for efficiency, these feed mixers produce a complete mix in just 3 to 5 minutes—whether you’re feeding dairy cattle, beef herds, or small ruminants. Available in capacities from 615 to 960 ft³, and fully customizable with multiple door and conveyor options, Jaylor Twin Auger Mixer Wagons are engineered to match the needs of your operation.

Twin Auger TMR Mixers FAQs

Jaylor’s 5000 Series Twin Auger TMR Mixers are available in a wide range of sizes, with capacities from 615 to 960 cubic feet (ft³). This flexibility makes them an ideal fit for a variety of operations—from mid-sized dairies and cow-calf herds to large feedlots requiring higher-volume feed mixers.

Jaylor Twin Auger TMR Mixers are designed to meet the demands of larger and more intensive feeding operations, including:

-

Large dairy farms and cow-calf operations

-

Feedlots of all sizes—also available as truck mount mixers for mobile feeding

-

High-capacity sheep and goat operations

-

Operations needing to process multiple bales, long-stem forage, and baleage into a uniform, consistent ration

Their high capacity, mixing speed, and custom options make them ideal for operations feeding hundreds—or thousands—of animals daily.

Key features include:

- Jaylor’s Patented Square-Cut Augers

- 3-Point Weight System

- Rapid Discharge Door

- Galvanized Discharge Conveyor

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir

Jaylor’s patented Square-Cut Augers create a consistent, well-blended Total Mixed Ration (TMR) that reduces sorting behavior in cattle and other ruminants. By producing a uniform mix of forage, silage, and grains, Jaylor twin auger feed mixers give operators full control over their herd’s nutrition—ensuring each animal receives a balanced diet with every bite.

Yes—Jaylor offers the 5600 Low-Profile Twin Auger TMR Mixer, specifically designed for operations with height restrictions or skid-steer loading setups. This compact yet powerful feed mixer provides the same consistent mix quality and dual auger performance in a design suited for barns or facilities with limited clearance.