M1670 Commercial Manure Spreader

Specifications

- Struck Capacity

- 670ft³ | 19.0m³

- Heaped Capacity

- 930ft³ | 26.3m³

- Overall Height

- 130in | 330cm

- Overall Length

- 380in | 965cm

- Overall Width

- 120in | 305cm

- Inside Body Height

- 65in | 165cm

- Inside Body Length

- 240in | 610cm

- Inside Body Width

- 60in | 152cm

- Loading Height

- 115in | 292cm

- Pto Speed

- 1000 RPM

- Beater Speed

- 405 RPM

- Recommended Tractor Class

- 150-250 HP

- Floor Thickness

- 1/4in | 6mm

- Side Wall Thickness

- 3/16in | 4.8mm

- Standard Tires

- 445/65 R22.5 Radial

- Recommended Tires

- 800/45 26.5 BIAS

- Standard Wheel Assembly

- Dual Sprung Axles

The Jaylor MMI mixer does a phenomenal job of handling wet distillers grains along with both high roughage rations and high energy corn rations.

We have a Jaylor 5575, and it's our second piece of Jaylor equipment. We've only had to do regular maintenance on the machine, which makes using the mixer simple and convenient.

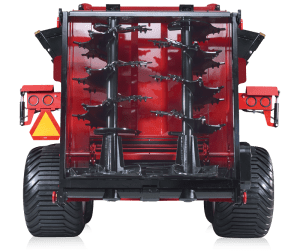

The Jaylor M1670 Manure Spreader is built tough, rugged, and offers more demand for its operators. The M1670 provides an increased struck capacity of 670ft3 and a 930ft3 heaped capacity for operators who demand more of their machines. In addition, the rear of the manure spreader features quick-attach vertical beaters and a hydraulic guillotine door. Paired together, these features allow the operator to achieve a full 40′ of consistent spread, and a 50′ spread when paired with the optional canopy addition.

“Our Jaylor Manure Spreader is easy on horsepower and retains a lot of moisture. It’s built for rugged terrain and it’s stood the test of time. We’re thrilled with the performane.

– Rob Sutton, Sutton Farm, Napanee Ontario, Canada

The M1670 Manure Spreader also offers commercial-grade cambered axles and breaks, making it easier to maneuver over challenging terrain and deep mud. 2-1/4″ bearings reinforce and hold the beaters in place, allowing for resistance from large stones, frozen chunks and other debris. Last but not least, a 7 position moveable axle allows operators to adjust their tire-wheel ratio, accommodating tractor size, terrain type and challenging wet conditions.

After you’ve been introduced to the Jaylor M1670 Manure Spreader, you’ll see firsthand why we say: “Because Simplicity Matters.”

Standard Features of M1670 Manure Spreader

Central Grease: The Jaylor M1670 comes standard with a central grease system. Each location that requires grease can be greased from three central locations. This allows an easy, reliable greasing process and reduced maintenance for operators.

Modular Driveshaft: The M1670’s driveline is made up of 3 PTO’s and 2 Driveshafts. This allows more resistance to bending and twisting. It’s also easy for operators to install and service.

Plastic Floors: Plastic floors come standard and reduce the overall wear on the floor from constant scraping and corrosion. The plastic floors also decrease power consumption by reducing friction.

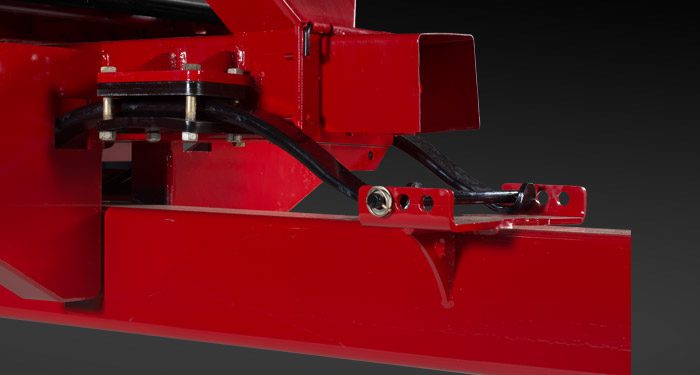

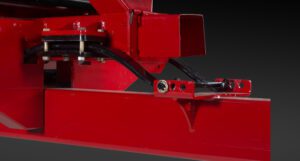

Adjustable Hanging Rear End: The Adjustable Hanging Rear End can be easily mounted at different rights to adjust the spread pattern of your machine. It’s easy to remove for maintenance and can be removed for hauling hay or silage. (Rear Beater Assembly Hooked)

Gear Boxes: The gearbox of the M1670 comes with helical gears, which contribute towards better wear resistance and power transfer. (RT 1000 Image)

Braked Tandem and Spring Axels: All models come standard with braked tandem or dual sprung axles. This allows for a smoother ride during applications and better performance on tough terrain.

Optional Features:

Plastic Wall Liner: Much like the standard plastic floor, the plastic wall liner will help reduce wear and tear on the spreader walls, reduce power consumption, and wear the gearboxes.

Plastic Beater Tray: Many operators choose to include a plastic beater tray because it helps reduce the overall wear and tear that the machine may encounter. It also reduces the wear on the beater paddles through the elimination of soil buildup.

Slide Kit: Helps the operator to maintain their desired tongue weight and alter the turn radius.

Canopy: Helps improve the spreading of fine materials like chicken manure and composts.

Light Covers: Cover lights help protect against common farm damage and improves the safety of the operator.

Tire Options: Jaylor offers many tire options to fit each customer’s needs. We also offer options for better flotation, traction and reduced soil compaction. This allows operators to start spreading several weeks earlier each spring, removing the need to wait for the ground to fully dry up before application.

Features

- Hydraulic Slide Axle (Optional)

- Hydraulic Brakes

- Overrun Clutch Gearbox Protection – Protects the integrity of the beaters, reduces wear and saves on power.

- High-Speed Cambered Commercial Axles

- Manual Implement Jack

- Wood Protection Rail

- Large Viewing Window – Allows for viewing inside the load, volume, debris. Monitor your load while you spread.

- Spring Suspension Tongue – Smoother Ride, for muddy fields and dry conditions.

- LED Road Lights

- Single Floor Chain Drive Gearbox

- Rugged Uni-body Design

- Grade 100 Floor Chain w/ One Piece Slat

- Spring Suspension

- 7 Position Adjustable Axle

- Safety Chain

Standard Features

Videos

Jaylor M1670 Manure Spreader Pen-Pack Demo