Twin Auger HD TMR Mixers

Built for heavier loads and tougher terrain, Jaylor’s HD Twin Auger TMR Mixers deliver the strength and stability large beef and dairy operations require —without sacrificing mix quality. Reinforced from the ground up, these large capacity feed mixers are made to perform in the most demanding conditions.

Jaylor's Twin Auger HD Mixer Line-Up

51250HD Twin Auger TMR Mixer

Capacity:

1125ft³ | 31.9m³

up to

1295ft³ | 36.7m³

*with extensions

4×5 Round Bales:

5 Bales

5×6 Round Bales:

3 Bales

3x4x8 Square Bales:

4.4 Bales

Height:

135in | 343cm

Length:

318in | 808cm

Drum Width:

102in | 259cm

Capacities noted above will vary with the density of the hay in the bales and other factors.

We’re here to discuss your needs and help you find the right mixer for your operation.

Save time while using 20% less horsepower.

Using 20% less horsepower and requiring less time per mix than conventional mixers — a Jaylor mixer reduces fuel consumption and ensures a longer operating life. It is conservatively estimated that Jaylor mixers can save $12,000 per year in operating costs compared to conventional mixers on a typical farm.

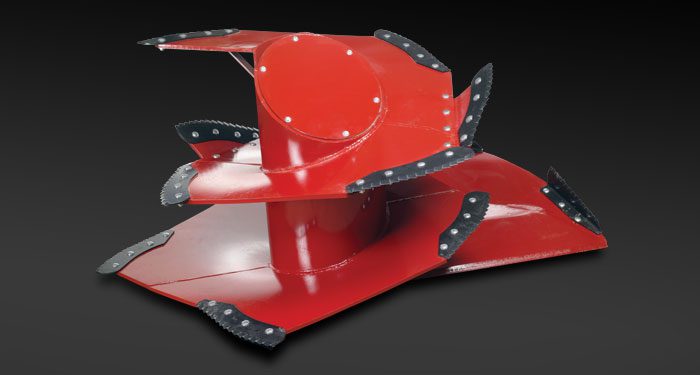

Tap on the Square-Cut Auger below to see what makes it such an innovation.

Have questions?

Unsure what machine is right for your operation?

Need to find a dealer or schedule a demo?

Jaylor Twin Auger HD TMR Mixers are engineered for operations that demand more from their feed mixer. Built with reinforced frames, heavy-duty axles, and thicker steel throughout, these mixer wagons are designed to handle heavier loads and rougher terrain—making them ideal for large dairies and cattle operations.

Compared to Jaylor’s standard Twin Auger TMR mixers, the HD series features stronger components and upgraded construction, allowing you to mix and transport rations up to 75% heavier. Each model includes a wide range of innovations, including; cast dual axle walking beam assemblies, durable hubs, and thick auger flighting and floors to ensure long-lasting performance.

Available in capacities from 740 to 1,295 cubic feet, Jaylor’s HD feed mixers deliver consistent, high-quality mixes with the strength to match. An optional Dinamica Generale scale system can upload as-fed data to the cloud in real-time, helping you track and optimize feed delivery right from your phone.

If you’re looking for a reliable, heavy-duty cattle feed mixer that’s built to last, the Jaylor Twin Auger HD Series delivers unmatched durability and performance in every mix.

- 5 Point Weight System

- Rapid Discharge Door

- Galvanized Discharge Conveyor

- Sloped Top Square Cut Augers

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Shear Bolt Protection

- Mixer Level Indicator

- Heavy-Duty Walking Beam Axles & Hubs

- Mix Viewing Window

- Restrictor Blades (2)

- Adjustable Cast Hitch

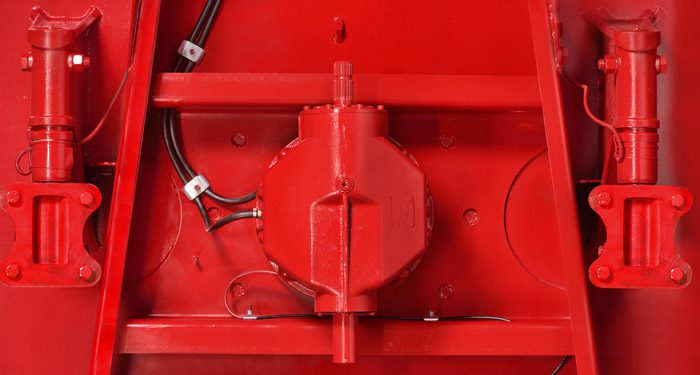

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir

- Central Greasing Bank

- Shaker Box

Our Jaylor 5850 Mixer is the fifth Jaylor Mixer we’ve owned. We like to keep current with the latest technology, and the consistent mix and feed from the machine keep us coming back. Choosing anything else would be a step backward for us. – Armstrong Manor Farm

Having a 13,000 head feedlot means we throw a lot at our Jaylor mixer. We use french fries in our feed, and the Jaylor 51250HD TMR Mixer gives us the best consistency of mix and vehicle maneuverability. – Kasko Cattle Co Ltd.

Twin Auger HD FAQs

Jaylor Twin Auger HD TMR Mixers are highly efficient at processing both round and square bales of forage. These heavy-duty cattle feed mixers can produce a consistent, uniform ration in just 3 to 5 minutes, helping to reduce sorting and support a balanced diet. This rapid forage processing makes Jaylor mixer wagons ideal for operations focused on feed efficiency and herd health.

Jaylor Twin Auger HD TMR Mixers are purpose-built for large-scale dairy and beef operations that demand more from their feed mixer. With a reinforced frame, cast dual-axle walking beam assemblies, and extra heavy-duty axles, hubs, wheels, and tires, these mixer wagons are designed to handle rough terrain and heavier loads—up to 75% more than standard models. This added strength makes them an ideal choice for consistent, efficient feeding with high-capacity TMR mixers in demanding conditions.

Jaylor Twin Auger HD TMR Mixers are available in a range of sizes, with capacities from 740 to 1,295 cubic feet (ft³). These heavy-duty, large capacity feed mixers are built to carry significantly heavier loads than standard models, with reinforced frames and upgraded components that make them ideal mixer wagons for large-scale dairy and cattle operations.

Yes—Jaylor offers a wide range of custom options to tailor your Twin Auger HD TMR Mixer to your operation’s specific feeding requirements. With over 30 years of experience in the cattle feeding equipment industry, Jaylor has developed solutions for nearly every feeding scenario. From a variety of discharge doors, chutes, and conveyors to other specialized mixer wagon features, your HD mixer can be fully customized for maximum performance and efficiency.

Key features include:

- Jaylor’s Patented Square-Cut Auger

- Heavy-Duty Walking Beam Axles & Hubs

- Heavy Duty Hydraulic Jack

- 5 Point Weight System with DG500 Indicator

- Rapid Discharge Door

- Galvanized Discharge Conveyor

- Tungsten Carbide Coated Knives

- Welded Mixing Chamber

- Structurally Reinforced Frame

- Shear Bolt Protection

- Mixer Level Indicator

- Mix Viewing Window

- Restrictor Blades (2)

- Adjustable Cast Hitch

- Heavy Duty Planetary Gearbox

- Patented Open Loop Oil Reservoir

- Central Greasing Bank

- Shaker Box