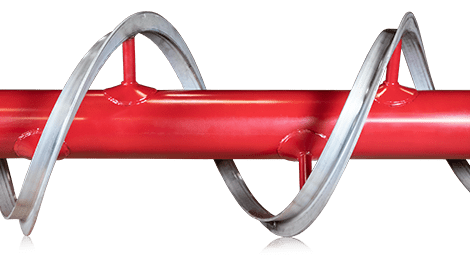

Jaylor is excited to announce the release of their patented ribbon style augers for Horizontal Mixers. These new style of augers provide additional benefits of reduced mix times by up to 1/3rd and increased mix capacity of 10-20% (measured by weight). Early adopters of the new system also note the improved ability of this style of auger to maintain large flake integrity.

Jaylor is well known for their patented square cut auger in their vertical mixers and is increasing manufacturing capacity to repeat the success with this improved auger design in their Quad Auger Horizontal Mixer. Also now available, the Heavy Duty Trailer models utilize the same commercial-grade components as the truck-mounted configuration, with proven reliability in demanding feedlot applications. Model H1650, the smallest of the 3 models offered, was revealed at the recent National Farm Machinery Show in Louisville, Kentucky.

Jaylor is well known for their patented square cut auger in their vertical mixers and is increasing manufacturing capacity to repeat the success with this improved auger design in their Quad Auger Horizontal Mixer. Also now available, the Heavy Duty Trailer models utilize the same commercial-grade components as the truck-mounted configuration, with proven reliability in demanding feedlot applications. Model H1650, the smallest of the 3 models offered, was revealed at the recent National Farm Machinery Show in Louisville, Kentucky.

Offered on the equipment is a state-of-the-art OrbitEvo 6520 Intelligent Controller. This proprietary hydrostatic planetary drive system and smart controller ensure power and performance that deliver feed accurately and efficiently. Similar in concept to a CVT, the OrbitEvo Controller automatically constantly varies the hydrostatic pump and motor for optimal load balancing. Continuous monitoring while mixing provides automatic load balancing and adjustments even regulating engine RPM to coincide with pump flow and pressure as well as motor flow and pressure. In addition, fine-tune control of auger RPM during feedout combined with a simple gravity chute allows even inexperienced operators to achieve single-pass feeding.

A 5-button joystick activates all the functions and the OrbitEvo 6520 takes care of the rest, drastically reducing training required for drivers. It incorporates 7 sensors logging system temperatures, oil level, pressures and flow for effective preventative maintenance and safely disengages on configurable over-threshold events ensuring system longevity. True to the Jaylor design philosophy that simplicity matters, this revolutionary TMR mixer significantly increases operational performance and efficiency while being exceptionally easy to use.

A 5-button joystick activates all the functions and the OrbitEvo 6520 takes care of the rest, drastically reducing training required for drivers. It incorporates 7 sensors logging system temperatures, oil level, pressures and flow for effective preventative maintenance and safely disengages on configurable over-threshold events ensuring system longevity. True to the Jaylor design philosophy that simplicity matters, this revolutionary TMR mixer significantly increases operational performance and efficiency while being exceptionally easy to use.

These advanced control systems enable independent mixer and truck engine speeds, reduce stress and wear on the entire system; truck engine, hydrostatic pump, and motor. In the low torque phase of cleanout the augers can be spun up to over 20RPM while the truck is close to idle. In addition to improved longevity, the proprietary OrbitEvo 6520 system combined with Ribbon Augers also shows results in fuel saving of up to 1 Gallon (3.8L) per hour, when compared to conventional Horizontal Mixers.

Jaylor Fabricating Inc., is located in Dufferin County, Ontario and manufacturers farm equipment, primarily TMR mixers for the beef and dairy industry. With 25 current patents and additional pending, the Jaylor Mixer has earned Jaylor the reputation as a leader in the business. Jaylor was built upon word of mouth and success on farms. Its reputation for high quality spread rapidly, ensuring Jaylor mixers were soon distributed throughout North America and over 50 countries world-wide.