Stationary

|

|

|

|

|

|

|

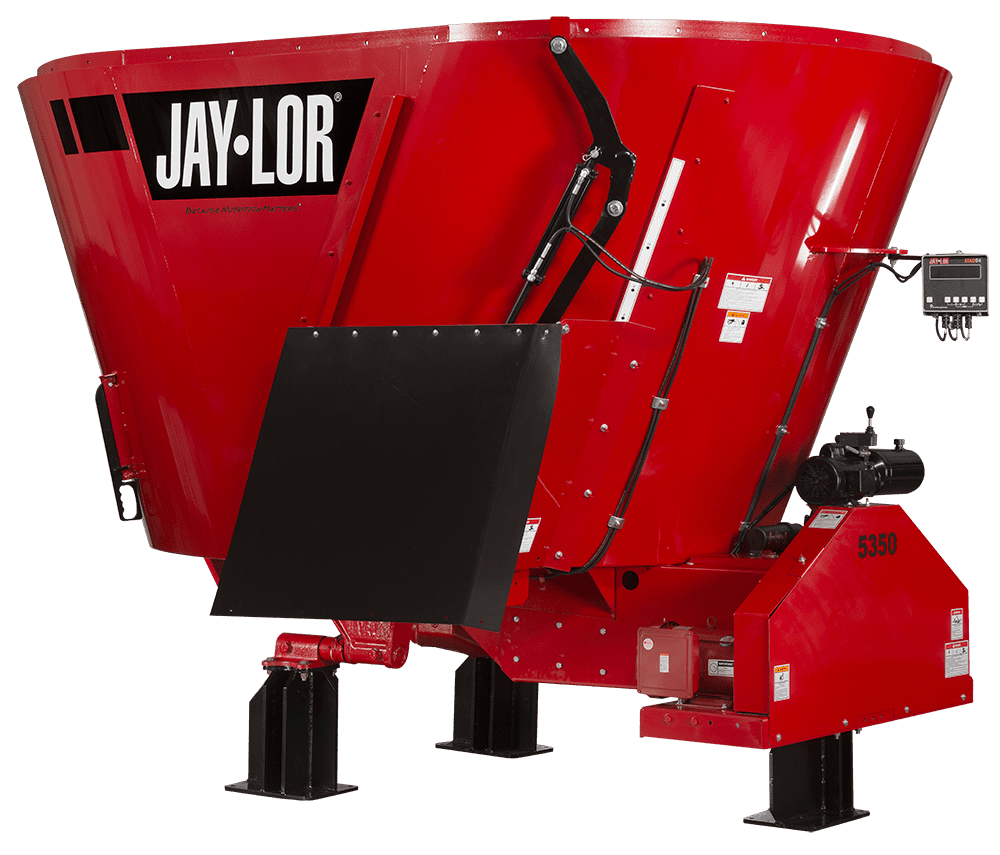

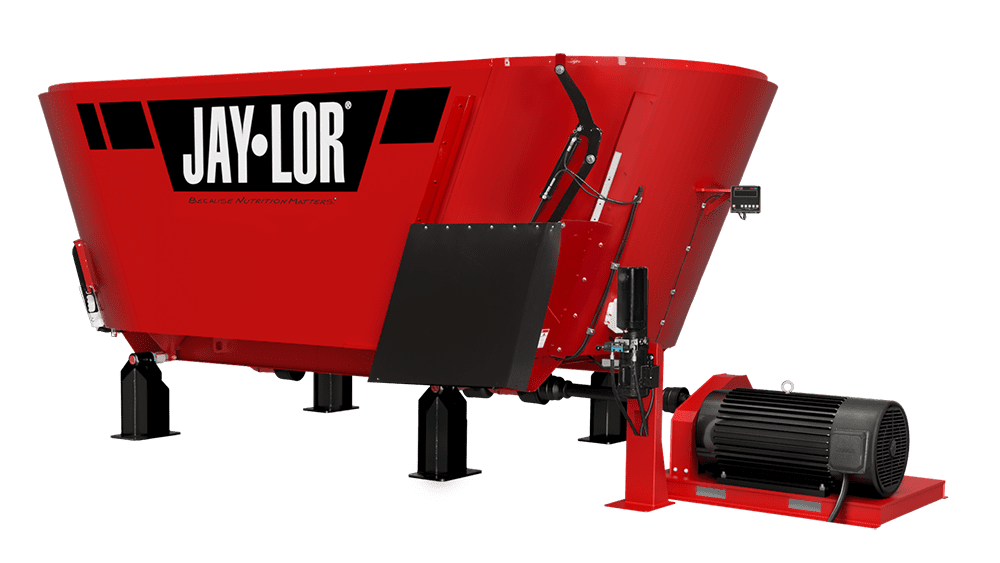

5350 Stationary Mixer

|

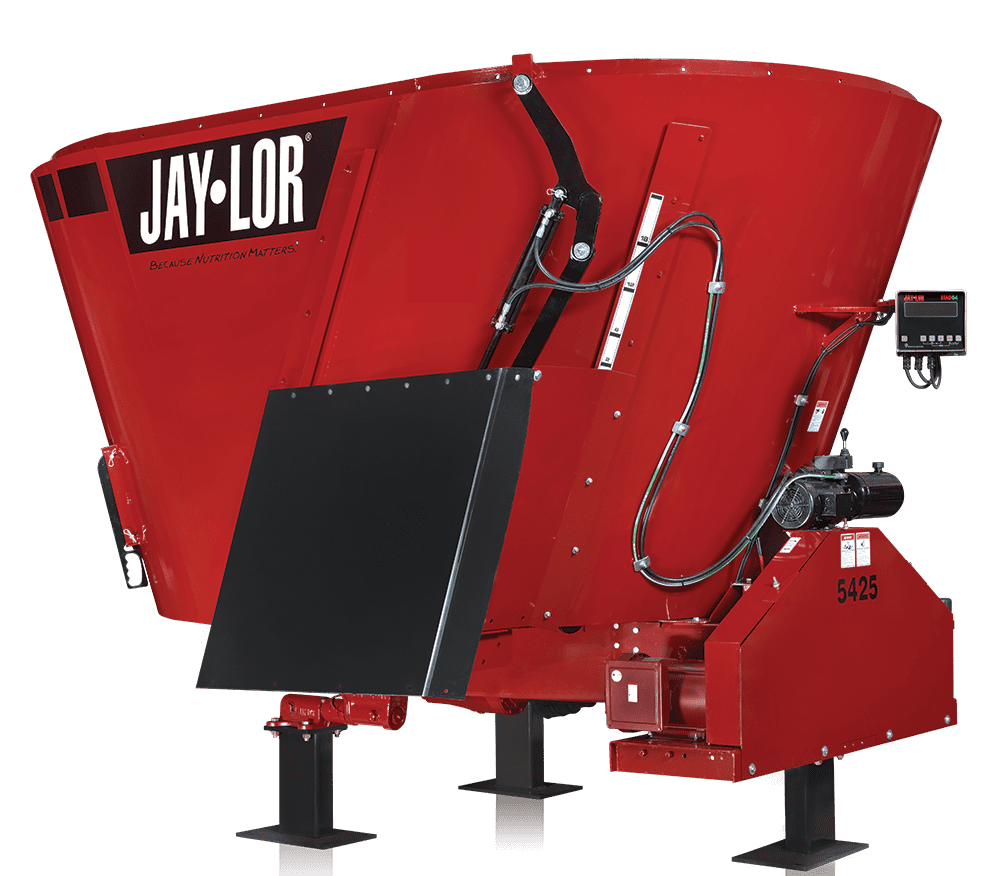

5425 Stationary Mixer

|

5750 Stationary Mixer

|

5850 Stationary Mixer

|

51000 Stationary Mixer

|

|

| Capacity No Ext. | 350ft3 | 9.9m3 | 450ft3 | 12.7m3 | 650ft3 | 18.4m3 | 800ft3 | 22.7m3 | 925ft3 | 26.2m3 |

| Capacity 8″ Extension | 380ft3 | 10.8m3 | 485ft3 | 13.7m3 | 700ft3 | 19.8m3 | 865ft3 | 24.5m3 | 990ft3 | 28.0m3 |

| Capacity 12″ Extension | 405ft3 | 11.5m3 | 515ft3 | 14.6m3 | 740ft3 | 21.0m3 | 910ft3 | 25.8m3 | 1045ft3 | 29.6m3 |

| Capacity 16″ Extension | 425ft3 | 12.0m3 | 540ft3 | 15.3m3 | 780ft3 | 22.1m3 | 960ft3 | 27.2m3 | 1095ft3 | 31.0m3 |

| Weight | 7300lbs | 3300kg | 7500lbs | 3400kg | 13000lbs | 5900kg | 17600lbs | 8000kg | 19800lbs | 9000kg |

| Height | 103in | 262cm | 108in | 274cm | 112in | 284cm | 108in | 274cm | 117in | 297cm |

| Drum Length | 138in | 351cm | 154in | 391cm | 236in | 600cm | 255in | 648cm | 265in | 673cm |

| Drum Width | 91in | 231cm | 97in | 246cm | 91in | 231cm | 97in | 246cm | 102in | 259cm |

| PTO Speed | 500 RPM | 500 RPM | 1000 RPM | 1000 RPM | 1000 RPM |

| Minimum HP Requirements | 2x 10 HP | 2x 10 HP | 150 HP | 200 HP | 250 HP |

| Auger Mix Speed | 18 RPM | 18 RPM | 41 RPM | 41 RPM | 41 RPM |

| Auger Cleanout Speed | 26 RPM | 26 RPM | 41 RPM | 41 RPM | 41 RPM |

| Number of Knives | 9 | 9 | 18 | 18 | 22 |

| Auger Flighting Thickness | 3/4in | 19mm | 3/4in | 19mm | 3/4in | 19mm | 3/4in | 19mm | 3/4in | 19mm |

| Discharge Height | 60in | 152cm | 60in | 152cm | 68in | 173cm | 68in | 173cm | 68in | 173cm |

| Door Opening Width | 42in | 107cm | 42in | 107cm | 42in | 107cm | 42in | 107cm | 42in | 107cm |

| Floor Thickness | 5/8in | 16mm | 5/8in | 16mm | 3/4in | 19mm | 3/4in | 19mm | 3/4in | 19mm |

| Drum Wall Thickness | 1/4in | 6mm | 1/4in | 6mm | 1/4in | 6mm | 1/4in | 6mm | 1/4in | 6mm |

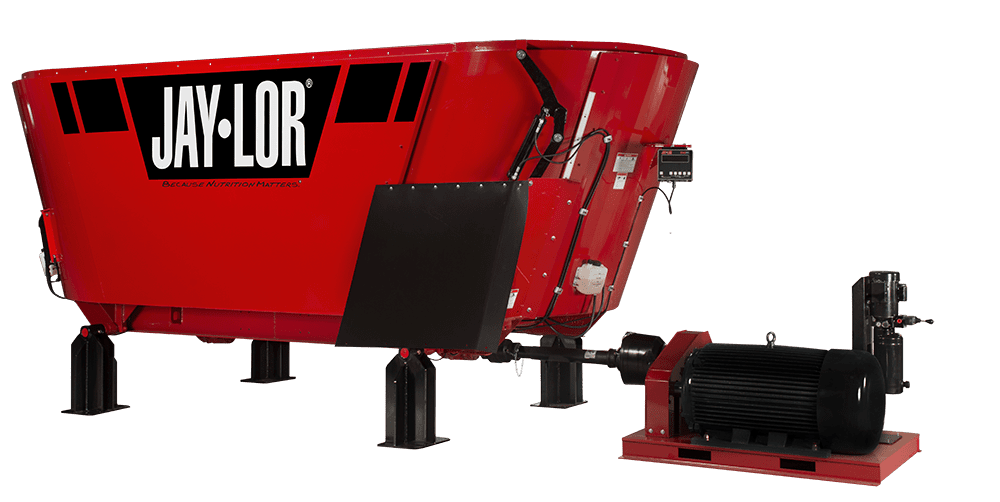

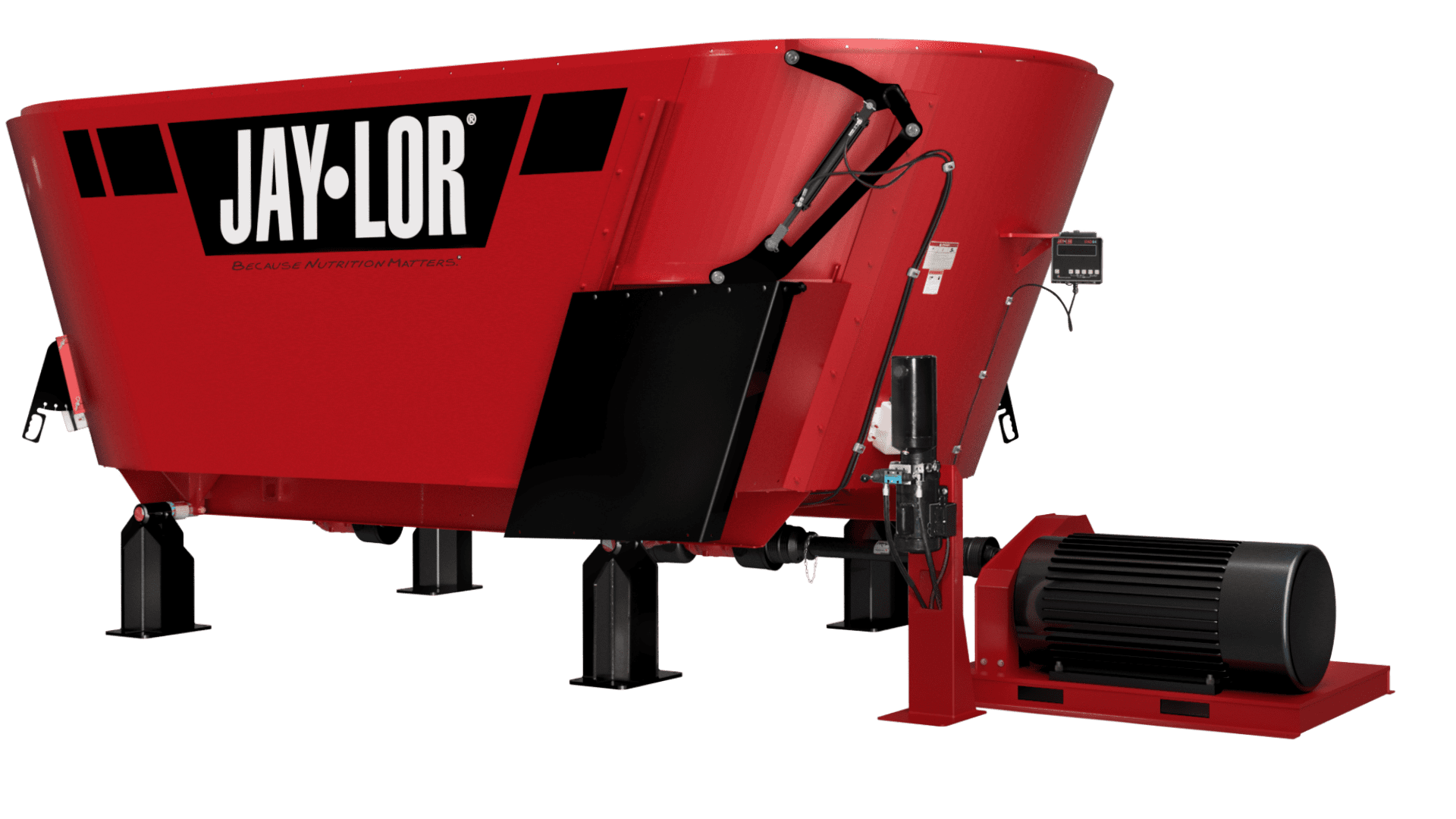

Jaylor stationary mixers are ideal for optimized cycle times on large operations, where feed storage is centralized and adequate electrical power is available. Low horsepower requirements of Jaylor’s patented Square-Cut auger translate to additional run-cost savings while retaining the ability to process forage and deliver a uniform ration that resists sorting.

Even though our stationary mixers are most often used for cattle feeding, they are also an ideal solution for composting materials, municipal waste management, digester feeding systems.

Following the purchase of our Jaylor 5425 mixer, cows have increased the rate of fat production, and they are much healthier. As a result, calving is more successful and previous challenges are virtually absent. – Guillaume Laroche, Rochela Ferme

Jaylor’s lineup of feed management systems allows for exemplary control of recipe formulation (based on daily DMI for each pen or batch), monitoring operator loading efficiency, and automatic feeding applications. All Jaylor stationary mixers are easy to install and are built to give owners years of trouble-free service.

Customers who have traditional tie-stalls and smaller farms will particularly enjoy the 5350 Stationary Mixer, powered by two 10HP single-phase electric motors. Jaylor’s Stationary Mixers have the same industry-leading capability for efficiently processing baled forage into uniform rations that resist sorting. All mixers come standard with patented square-cut augers and the full range of innovations and warranties.

Let’s discuss the total cost of ownership savings a stationary mixer could bring to your operation.